Industrial Revolution

2007 Schools Wikipedia Selection. Related subjects: General history

The Industrial Revolution was the major shift of technological, socioeconomic and cultural conditions in the late 18th and early 19th century that began in Britain and spread throughout the world. During that time, an economy based on manual labour was replaced by one dominated by industry and the manufacture of machinery. It began with the mechanisation of the textile industries and the development of iron-making techniques, and trade expansion was enabled by the introduction of canals, improved roads and railways. The introduction of steam power (fuelled primarily by coal) and powered machinery (mainly in textile manufacturing) underpinned the dramatic increases in production capacity. The development of all-metal machine tools in the first two decades of the 19th century facilitated the manufacture of more production machines for manufacturing in other industries.

The period of time covered by the Industrial Revolution varies with different historians. Eric Hobsbawm held that it 'broke out' in the 1780s and was not fully felt until the 1830s or 1840s, while T.S. Ashton held that it occurred roughly between 1760 and 1830 (in effect the reigns of George III, The Regency, and George IV).

The effects spread throughout Western Europe and North America during the 19th century, eventually affecting most of the world. The impact of this change on society was enormous and is often compared to the Neolithic revolution, when various human subgroups embraced agriculture and in the process, forswore the nomadic lifestyle.

The first Industrial Revolution merged into the Second Industrial Revolution around 1850, when technological and economic progress gained momentum with the development of steam-powered ships, railways, and later in the nineteenth century with the internal combustion engine and electrical power generation. At the turn of the century, innovator Henry Ford, father of the assembly line, stated, "There is but one rule for the industrialist, and that is: Make the highest quality goods possible at the lowest cost possible, paying the highest wages possible."

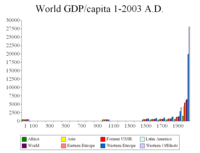

It has been argued that GDP per capita was much more stable and progressed at a much slower rate until the Industrial Revolution and the emergence of the modern capitalist economy, and that it has since increased rapidly in capitalist countries.

Some twentieth century historians such as John Clapham and Nicholas Crafts have argued that the process of economic and social change took place gradually and the term revolution is not a true description of what took place. This is still a subject of debate amongst historians.

Nomenclature

The term Industrial Revolution applied to technological change was common in the 1830s. Louis-Auguste Blanqui in 1837 spoke of la révolution industrielle. Friedrich Engels in The Condition of the Working Class in England in 1844 spoke of "an industrial revolution, a revolution which at the same time changed the whole of civil society".

In his book Keywords: A Vocabulary of Culture and Society, Raymond Williams states in the entry for Industry: The idea of a new social order based on major industrial change was clear in Southey and Owen, between 1811 and 1818, and was implicit as early as Blake in the early 1790s and Wordsworth at the turn of the century.

Credit for popularising the term may be given to Arnold Toynbee, whose lectures given in 1881 gave a detailed account of the process.

Innovations

The invention of the steam engine was the most important innovation of the Industrial Revolution. James Watt, later to be a member of the Lunar Society, developed the idea of using steam to power machines into a practicality thus enabling rapid development of efficient semi-automated factories on a previously unimaginable scale. This was applied to all aspects of industry and engineering. Earlier improvements in iron smelting and metal working based on the use of coke rather than charcoal allowed Watt and others before him to exploit the possibilities of using steam as a form of power. Earlier in the 18th century, the textile industry had harnessed water power to drive improved spinning machines and looms. These textile mills became the model for the organisation of human labour in factories, epitomised by Cottonopolis the name given to the vast collection of mills, factories and administration offices based in Manchester.

Besides the innovation of machinery in factories, the assembly line greatly improved efficiency. With a series of men trained to do a single task on a product, then having it moved along to the next worker, the number of finished goods also rose significantly.

Transfer of knowledge

Knowledge of new innovation was spread by several means. Workers who were trained in the technique might move to another employer or might be poached. A common method was for someone to make a study tour, gathering information where he could. During the whole of the Industrial Revolution and for the century before, all European countries and America engaged in study-touring; some nations, like Sweden and France, even trained civil servants or technicians to undertake it as a matter of state policy. In other countries, notably Britain and America, this practice was carried out by individual manufacturers anxious to improve their own methods. Study tours were common then, as now, as was the keeping of travel diaries. Records made by industrialists and technicians of the period are an incomparable source of information about their methods.

Another means for the spread of innovation was by the network of informal philosophical societies—like the Lunar Society of Birmingham—in which members met to discuss science and often its application to manufacturing. Some of these societies published volumes of proceedings and transactions, and the London-based Royal Society of Arts published an illustrated volume of new inventions, as well as papers about them in its annual Transactions.

There were publications describing technology. Encyclopedias such as Harris's Lexicon technicum (1704) and Dr. Abraham Rees's Cyclopaedia (1802-1819) contain much of value. Cyclopaedia contains an enormous amount of information about the science and technology of the first half of the Industrial Revolution, very well illustrated by fine engravings. Foreign printed sources such as the Descriptions des Arts et Métiers and Diderot's Encyclopédie explained foreign methods with fine engraved plates.

Periodical publications about manufacturing and technology began to appear in the last decade of the 18th century, and many regularly included notice of the latest patents. Foreign periodicals, such as the Annales des Mines, published accounts of travels made by French engineers who observed British methods on study tours.

Industry

Mining

Coal mining in Britain, particularly in South Wales started early. Before the steam engine, pits were often shallow bell pits following a seam of coal along the surface which were abandoned as the coal was extracted. In other cases, if the geology was favourable, the coal was mined by means of an adit driven into the side of a hill. Shaft mining was done in some areas, but the limiting factor was the problem of removing water. It could be done by hauling buckets of water up the shaft or to a sough (a tunnel driven into a hill to drain a mine). In either case, the water had to be discharged into a stream or ditch at a level where it could flow away by gravity. The introduction of the steam engine greatly facilitated the removal of water and enabled shafts to be made deeper, enabling more coal to be extracted. These were developments that had begun before the Industrial Revolution, but the adoption of James Watt's more efficient steam engine with its separate condenser from the 1770s reduced the fuel costs of engines, making mines more profitable.

Metallurgy

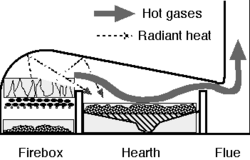

The major change in the metal industries during the era of the Industrial Revolution was the replacement of organic fuels based on wood with fossil fuel based on coal. Much of this happened somewhat before the Industrial Revolution, based on innovations by Sir Clement Clerke and others from 1678, using coal reverberatory furnaces known as cupolas. These were operated by the flames, which contained carbon monoxide, playing on the ore and reducing the oxide to metal. This has the advantage that impurities (such as sulfur) in the coal do not migrate into the metal. This technology was applied to lead from 1678 and to copper from 1687. It was also applied to iron foundry work in the 1690s, but in this case the reverberatory furnace was known as an air furnace. The foundry cupola is a different (and later) innovation.

This was followed by Abraham Darby, who made great strides using coke to fuel his blast furnaces at Coalbrookdale in 1709. However, the coke pig iron he made was used mostly for the production of cast iron goods such as pots and kettles. He had an advantage over his rivals in that his pots, cast by his patented process, were thinner and cheaper than those of his rivals. Coke pig iron was hardly used to produce bar iron in forges until the mid 1750s, when his son Abraham Darby II built Horsehay and Ketley furnaces (not far from Coalbrookdale). By then, coke pig iron was cheaper than charcoal pig iron.

Bar iron for smiths to forge into consumer goods was still made in finery forges, as it long had been. However, new processes were adopted in the ensuing years. The first is referred to today as potting and stamping, but this was superseded by Henry Cort's puddling process. From 1785, perhaps because the improved version of potting and stamping was about to come out of patent, a great expansion in the output of the British iron industry began. The new processes did not depend on the use of charcoal at all and were therefore not limited by charcoal sources.

Up to that time, British iron manufacturers had used considerable amounts of imported iron to supplement native supplies. This came principally from Sweden from the mid 17th century and later also from Russia from the end of the 1720s. However, from 1785, imports decreased because of the new iron making technology, and Britain became an exporter of bar iron as well as manufactured wrought iron consumer goods.

Since iron was becoming cheaper and more plentiful, it also became a major structural material following the building of the innovative Iron Bridge in 1778 by Abraham Darby III.

An improvement was made in the production of steel, which was an expensive commodity and used only where iron would not do, such as for the cutting edge of tools and for springs. Benjamin Huntsman developed his crucible steel technique in the 1740s. The raw material for this was blister steel, made by the cementation process.

The supply of cheaper iron and steel aided the development of boilers and steam engines, and eventually railways. Improvements in machine tools allowed better working of iron and steel and further boosted the industrial growth of Britain.

Chemicals

The large scale production of chemicals was an important development during the Industrial Revolution. The first of these was the production of sulfuric acid by the lead chamber process invented by the Englishman John Roebuck (James Watt's first partner) in 1746. He was able to greatly increase the scale of the manufacture by replacing the relatively expensive glass vessels formerly used with larger, less expensive chambers made of riveted sheets of lead. Instead of a few pounds at a time, he was able to make a hundred pounds (45 kg) or so at a time in each of the chambers.

The production of an alkali on a large scale became an important goal as well, and Nicolas Leblanc succeeded in 1791 in introducing a method for the production of sodium carbonate. The Leblanc process was a reaction of sulfuric acid with sodium chloride to give sodium sulfate and hydrochloric acid. The sodium sulfate was heated with limestone (calcium carbonate) and coal to give a mixture of sodium carbonate and calcium sulfide. Adding water separated the soluble sodium carbonate from the calcium sulfide. The process produced a large amount of pollution (the hydrochloric acid was initially vented to the air, and calcium sulfide was a useless waste product) but proved economical over the previous method of deriving it from wood ashes, barilla, or kelp.

These two chemicals were very important because they enabled the introduction of a host of other inventions, replacing many small-scale operations with more cost-effective and controllable processes. Sodium carbonate had many uses in the glass, textile, soap, and paper industries. Early uses for sulfuric acid included pickling (removing rust) iron and steel, and for bleaching cloth.

The development of bleaching powder ( calcium hypochlorite) by Scottish chemist Charles Tennant in about 1800, based on the discoveries of French chemist Claude Louis Berthollet, revolutionized the bleaching processes in the textile industry by dramatically reducing the time required (from months to days) for the traditional process then in use, which required repeated exposure to the sun in bleach fields after soaking the textiles with alkali or sour milk. Tennant's factory at St. Rollox, North Glasgow, became the largest chemical plant in the world.

Steam power

The development of the stationary steam engine was an essential early element of the Industrial Revolution; however, for most of the period of the Industrial Revolution, the majority of industries still relied on wind and water power as well as horse and man-power for driving small machines.

The industrial use of steam power started with Thomas Savery in 1698. He constructed and patented in London the first engine, which he called the "Miner's Friend" since he intended it to pump water from mines. This machine used steam at 8 to 10 atmospheres (120-150 psi and did not use a piston and cylinder but applied the steam pressure directly on to the surface of water in a cylinder to force it along an outlet pipe. It also used condensed steam to produce a partial vacuum to suck water into the cylinder. It generated about one horsepower (hp). It was used as a low-lift water pump in a few mines and numerous water works, but it was not a success since it was limited in the height it could raise water and was prone to boiler explosions.

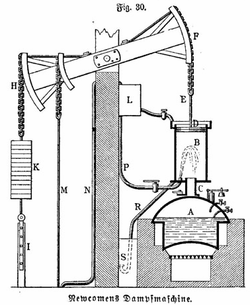

The first successful machine was the atmospheric engine, a low performance steam engine invented by Thomas Newcomen in 1712. Newcomen apparently conceived his machine quite independently of Savery. His engines used a piston and cylinder, and it operated with steam just above atmospheric pressure which was used to produce a partial vacuum in the cylinder when condensed by jets of cold water. The vacuum sucked a piston into the cylinder which moved under pressure from the atmosphere. The engine produced a succession of power strokes which could work a pump but could not drive a rotating wheel. They were successfully put to use for pumping out mines in Britain, with the engine on the surface working a pump at the bottom of the mine by a long connecting rod. These were large machines, requiring a lot of capital to build, but produced about 5 hp. They were inefficient, but when located where coal was cheap at pit heads, they were usefully employed in pumping water from mines. They opened up a great expansion in coal mining by allowing mines to go deeper. Despite using a lot of fuel, Newcomen engines continued to be used in the coalfields until the early decades of the nineteenth century because they were reliable and easy to maintain.

By 1729, when Newcomen died, his engines had spread to France, Germany, Austria, Hungary and Sweden. A total of 110 are known to have been built by 1733 when the patent expired, of which 14 were abroad. A total of 1,454 engines had been built by 1800.

Its working was fundamentally unchanged until James Watt succeeded in making his Watt steam engine in 1769, which incorporated a series of improvements, especially the separate steam condenser chamber. This improved engine efficiency by about a factor of five saving 75% on coal costs. The Watt steam engine's ability to drive rotary machinery also meant it could be used to drive a factory or mill directly. They were commercially very successful, and by 1800, the firm Boulton & Watt had constructed 496 engines, with 164 acting as pumps, 24 serving blast furnaces, and 308 to power mill machinery. Most of the engines generated between 5 to 10 hp.

The development of machine tools, such as the lathe, planing and shaping machines powered by these engines, enabled all the metal parts of the engines to be easily and accurately cut and in turn made it possible to build larger and more powerful engines.

Until about 1800, the most common pattern of steam engine was the beam engine, which was built within a stone or brick engine-house, but around that time various patterns of portable (readily removable engines, but not on wheels) engines were developed, such as the table engine.

Richard Trevithick, a Cornish blacksmith, began to use high pressure steam with improved boilers in 1799. This allowed engines to be compact enough to be used on mobile road and rail locomotives and steam boats.

In the early 19th century after the expiration of Watt's patent, the steam engine had many improvements by a host of inventors and engineers.

Textile manufacture

In the early 18th century, British textile manufacture was based on wool which was processed by individual artisans, doing the spinning and weaving on their own premises. This system is called a cottage industry. Flax and cotton were also used for fine materials, but the processing was difficult because of the pre-processing needed, and thus goods in these materials made only a small proportion of the output.

Use of the spinning wheel and hand loom restricted the production capacity of the industry, but incremental advances increased productivity to the extent that manufactured cotton goods became the dominant British export by the early decades of the 19th century. India was displaced as the premier supplier of cotton goods.

Lewis Paul and John Wyatt of Birmingham patented the Roller Spinning machine and the flyer-and-bobbin system for drawing wool to a more even thickness. Paul and Wyatt opened a mill in Birmingham which used their new rolling machine powered by a donkey. In 1743, a factory was opened in Northampton; fifty spindles turned on five of Paul and Wyatt's machines proving more successful than their first Mill and operated until 1764. Lewis Paul also invented the hand driven carding machine. Using two sets of rollers that travelled at different speeds, it was later used in the first cotton spinning mill. Lewis's invention was later developed and improved by Richard Arkwright and Samuel Crompton, although this came about under great suspicion after a fire at Daniel Bourn's factory in Leominster which specifically used Paul and Wyatt's spindles. Borne produced a similar patent in the same year. Other inventors increased the efficiency of the individual steps of spinning (carding, twisting and spinning, and rolling) so that the supply of yarn increased greatly, which fed a weaving industry that was advancing with improvements to shuttles and the loom or 'frame'. The output of an individual labourer increased dramatically, with the effect that the new machines were seen as a threat to employment, and early innovators were attacked and their inventions destroyed.

To capitalize upon these advances, it took a class of entrepreneurs, of which the most famous is Richard Arkwright. He is credited with a list of inventions, but these were actually developed by people such as Thomas Highs and John Kay; Arkwright nurtured the inventors, patented the ideas, financed the initiatives, and protected the machines. He created the cotton mill which brought the production processes together in a factory, and he developed the use of power — first horse power, then water power and finally steam power — which made cotton manufacture a mechanized industry.

Factories

Industrialisation also led to the creation of the factory. John Lombe's water-powered silk mill at Derby was operational by 1721. In 1746, an integrated brass mill was working at Warmley near Bristol. Raw material went in at one end, was smelted into brass and was turned into pans, pins, wire, and other goods. Housing was provided for workers on site.

Josiah Wedgwood and Matthew Boulton were other prominent early industrialists.

The factory system was largely responsible for the rise of the modern city, as workers migrated into the cities in search of employment in the factories. Nowhere was this better illustrated than the mills and associated industries of Manchester, nicknamed Cottonopolis, and arguably the world's first industrial city. For much of the 19th century, production was done in small mills, which were typically powered by water and built to serve local needs.

The transition to industrialisation was not wholly smooth. For example, a group of English workers known as Luddites formed to protest against industrialisation and sometimes sabotaged factories.

One of the earliest reformers of factory conditions was Robert Owen.

Machine tools

The Industrial Revolution could not have developed without machine tools, for they enabled manufacturing machines to be made. They have their origins in the tools developed in the 18th century by makers of clocks and watches and scientific instrument makers to enable them to batch-produce small mechanisms. The mechanical parts of early textile machines were sometimes called 'clock work' because of the metal spindles and gears they incorporated. The manufacture of textile machines drew craftsmen from these trades and is the origin of the modern engineering industry.

Machines were built by various craftsmen— carpenters made wooden framings, and smiths and turners made metal parts. A good example of how machine tools changed manufacturing took place in Birmingham, England, in 1830. The invention of a new machine by William Joseph Gillott, William Mitchell and James Stephen Perry allowed mass manufacture of robust, cheap steel pen nibs; the process had been laborious and expensive. Because of the difficulty of manipulating metal and the lack of machine tools, the use of metal was kept to a minimum. Wood framing had the disadvantage of changing dimensions with temperature and humidity, and the various joints tended to rack (work loose) over time. As the Industrial Revolution progressed, machines with metal frames became more common, but they required machine tools to make them economically. Before the advent of machine tools, metal was worked manually using the basic hand tools of hammers, files, scrapers, saws and chisels. Small metal parts were readily made by this means, but for large machine parts, production was very laborious and costly.

Apart from workshop lathes used by craftsmen, the first large machine tool was the cylinder boring machine used for boring the large-diameter cylinders on early steam engines. The planing machine, the slotting machine and the shaping machine were developed in the first decades of the 19th century. Although the milling machine was invented at this time, it was not developed as a serious workshop tool until during the Second Industrial Revolution.

Military production had a hand in the development of machine tools. Henry Maudslay, who trained a school of machine tool makers early in the 19th century, was employed at the Royal Arsenal, Woolwich, as a young man where he would have seen the large horse-driven wooden machines for cannon boring made and worked by the Verbruggans. He later worked for Joseph Bramah on the production of metal locks, and soon after he began working on his own. He was engaged to build the machinery for making ships' pulley blocks for the Royal Navy in the Portsmouth Block Mills. These were all metal and were the first machines for mass production and making components with a degree of interchangeability. The lessons Maudslay learned about the need for stability and precision he adapted to the development of machine tools, and in his workshops he trained a generation of men to build on his work, such as Richard Roberts, Joseph Clement and Joseph Whitworth.

James Fox of Derby had a healthy export trade in machine tools for the first third of the century, as did Matthew Murray of Leeds. Roberts was a maker of high-quality machine tools and a pioneer of the use of jigs and gauges for precision workshop measurement.

Transportation

At the beginning of the Industrial Revolution, inland transport was by navigable rivers and roads, with coastal vessels employed to move heavy goods by sea. Railways or wagon ways were used for conveying coal to rivers for further shipment, but canals had not yet been constructed. Animals supplied all of the motive power on land, with sails providing the motive power on the sea.

The Industrial Revolution improved Britain’s transport infrastructure with a turnpike road network, a canal, and waterway network, and a railway network. Raw materials and finished products could be moved more quickly and cheaply than before. Improved transportation also allowed new ideas to spread quickly.

Navigable rivers

All the major rivers of the United Kingdom were made more navigable during the Industrial Revolution. The Severn, in particular, was used for the movement of goods to the Midlands which had been imported into Bristol from abroad, and for the export of goods from centres of production in Shropshire such as iron goods from Coalbrookdale. Transport was by way of trows—small sailing vessels which could pass the various shallows and bridges in the river. The trows could navigate the Bristol Channel to the South Wales ports and Somerset ports, such as Bridgwater and even as far as France.

Coastal sail

Sailing vessels had long been used for moving goods round the British coast. The trade transporting coal to London from Newcastle had begun in medieval times. The major international seaports such as London, Bristol, and Liverpool, were the means by which raw materials such as cotton might be imported and finished goods exported. Transporting goods onwards within Britain by sea was common during the whole of the Industrial Revolution and only fell away with the growth of the railways at the end of the period.

Canals

Canals began to be built in the late eighteenth century to link the major manufacturing centres in the Midlands and north with seaports and with London, at that time the largest manufacturing centre in the country. Canals were the first technology to allow bulk materials to be easily transported across country. A single canal horse could pull a load dozens of times larger than a cart at a faster pace. By the 1820s, a national network was in existence. Canal construction served as a model for the organisation and methods later used to construct the railways. They were eventually largely superseded as profitable commercial enterprises by the spread of the railways from the 1840s on.

Britain's canal network, together with its surviving mill buildings, is one of the most enduring features of the early Industrial Revolution to be seen in Britain.

Roads

Much of the original British road system was poorly maintained by thousands of local parishes, but from the 1720s (and occasionally earlier) turnpike trusts were set up to charge tolls and maintain some roads. Increasing numbers of main roads were turnpiked from the 1750s to the extent that almost every main road in England and Wales was the responsibility of some turnpike trust. New engineered roads were built by John Metcalf, Thomas Telford and John Macadam. The major turnpikes radiated from London and were the means by which the Royal Mail was able to reach the rest of the country. Heavy goods transport on these roads was by means of slow broad wheeled carts hauled by teams of horses. Lighter goods were conveyed by smaller carts or by teams of pack horses. Stage coaches transported rich people. The less wealthy walked or paid to ride on a carriers cart.

Railways

Wagonways for moving coal in the mining areas had started in the 17th century and were often associated with canal or river systems for the further movement of coal. These were all horse drawn or relied on gravity, with a stationary steam engine to haul the wagons back to the top of the incline. The first applications of the steam locomotive were on waggon or plate ways (as they were then often called from the cast iron plates used). Horse-drawn public railways did not begin until the early years of the 19th century. Steam-hauled public railways began with the Liverpool and Manchester and Stockton and Darlington Railways of the late 1820s. The construction of major railways connecting the larger cities and towns began in the 1830s but only gained momentum at the very end of the first Industrial Revolution.

After many of the workers had completed the railways, they did not return to their rural lifestyles but instead remained in the cities, providing additional workers for the factories.

Railways helped Britain's trade enormously, providing a quick and easy method of transport.

Social effects

In terms of social structure, the Industrial Revolution witnessed the triumph of a middle class of industrialists and businessmen over a landed class of nobility and gentry.

Ordinary working people found increased opportunities for employment in the new mills and factories, but these were often under strict working conditions with long hours of labour dominated by a pace set by machines. Harsh working conditions were prevalent long before the industrial revolution took place as well. Pre-industrial society was very static and often cruel—child labour, dirty living conditions and long working hours were just as prevalent before the Industrial Revolution.

Child labour

Child labour had existed before the Industrial Revolution.

The Industrial Revolution led to a population increase. Industrial workers were better paid than those in agriculture. With more money, women ate better, had healthier babies, who were themselves better fed. Death rates declined, and the distribution of age in the population became more youthful. There was limited opportunity for education, and children were expected to work. Employers also liked that they could pay a child less than an adult.

Politicians and the government tried to limit child labour by law, but factory owners resisted; some felt that they were aiding the poor by giving their children money to buy food to avoid starvation, and others simply welcomed the cheap labour. In 1833, the first law against child labour, the Factory Act of 1833, was passed in England: Children younger than nine were not allowed to work, children were not permitted to work at night, and the work day of youth under the age of 18 was limited to twelve hours. Factory inspectors supervised the execution of the law. About ten years later, the employment of children and women in mining was forbidden. These laws decreased the number of child labourers; however, child labour remained in Europe up to the 20th century.

Housing

Living conditions during the Industrial Revolution varied from the splendour of the homes of the owners to the squalor of the lives of the workers. Cliffe Castle, Keighley, is a good example of how the newly rich chose to live. This is a large home modelled loosely on a castle with towers and garden walls. The home is very large and was surrounded by a massive garden, the estate itself stretching for a number of miles. Cliffe Castle is now open to the public as a museum.

Poor people lived in small houses in cramped streets. These homes would share toilet facilities, have open sewers and would be at risk of damp. Conditions did improve during the 19th century as public health acts were introduced covering things such as sewage, hygiene and making some boundaries upon the construction of homes. Not everybody lived in homes like these. The Industrial Revolution created a larger middle class of professionals such as lawyers and doctors. The conditions for the poor improved over the course of the 19th century because of government and local plans which led to cities becoming cleaner places, but life had not been easy for the poor before industrialisation.

Luddites

The rapid industrialisation of the English economy cost many craft workers their jobs. The textile industry in particular industrialized early, and many weavers found themselves suddenly unemployed since they could no longer compete with machines which only required relatively limited (and unskilled) labour to produce more cloth than a single weaver. Many such unemployed workers, weavers and others, turned their animosity towards the machines that had taken their jobs and began destroying factories and machinery. These attackers became known as Luddites, supposedly followers of Ned Ludd, a folklore figure. The first attacks of the Luddite movement began in 1811. The Luddites rapidly gained popularity, and the British government had to take drastic measures to protect industry.

Organization of Labour

Conditions for the working class had been bad for millennia. The Industrial Revolution, however, concentrated labour into mills, factories and mines, and this facilitated the organisation of trade unions to help advance the interests of working people. The power of a union could demand better terms by withdrawing all labour and causing a consequent cessation of production. Employers had to decide between giving in to the union demands at a cost to themselves or suffer the cost of the lost production. Skilled workers were hard to replace, and these were the first groups to successfully advance their conditions through this kind of bargaining.

The main method the unions used to effect change was strike action. Strikes were painful events for both sides, the unions and the management. The management was affected because strikes took their working force away for a long period of time; the unions had to deal the loss of income as well as with riot police and various middle class prejudices that striking workers were the same as criminals. The strikes often led to violent and bloody clashes between police or military and workers. Factory managers usually reluctantly gave in to various demands made by strikers, but the conflict was generally long standing.

In England, the Combination Act forbade workers to form any kind of trade union from 1799 until its repeal in 1824. Even after this, unions were still severely restricted.

In 1842, a General Strike involving cotton workers and colliers and organised through the Chartist movement stopped production across Great Britain.

Other effects

The application of steam power to the industrial processes of printing supported a massive expansion of newspaper and popular book publishing, which reinforced rising literacy and demands for mass political participation.

During the Industrial Revolution, the life expectancy of children increased dramatically. The percentage of the children born in London who died before the age of five decreased from 74.5% in 1730 - 1749 to 31.8% in 1810 - 1829. Besides, there was a significant increase in worker wages during the period 1813-1913.

The Industrial Revolution had significant impacts on the structure of society. Prior to its rise, the public and private spheres held strong overlaps; work was often conducted through the home and thus was shared in many cases by wife and husband. However, during this period the two began to separate, with work and home life considered quite distinct from one another. This shift made it necessary for one partner to maintain the home and care for children. Women, holding the distinction of being able to breastfeed, thus more often maintained the home, with men making up a sizeable fraction of the workforce. With much of the family income coming from men, then, their power in relation to women increased further, with the latter often dependent on men's income. This had enormous impacts on the defining of gender roles and was effectively the model for what was later termed the traditional family.

However, the need for a large workforce and resulting wages also enticed many women into industrial work, where they were often paid much less in relation to men. This was mostly because of a lack of organised labour among women to push for benefits and wage increases, and in part to ensure women's continued dependence on a man's income to survive.

Intellectual paradigms

Capitalism

The advent of The Enlightenment provided an intellectual framework which welcomed the practical application of the growing body of scientific knowledge — a factor evidenced in the systematic development of the steam engine, guided by scientific analysis, and the development of the political and sociological analyses, culminating in Adam Smith's The Wealth of Nations. One of the main arguments for capitalism is that industrialisation have increased wealth for all, as evidenced by raising life expectancy, reduced working hours, and no work for children and the elderly.

Criticism

Marxism

According to Karl Marx, industrialisation polarised society into the bourgeoisie (those who own the means of production, the factories and the land) and the much larger proletariat (the working class who actually perform the labour necessary to extract something valuable from the means of production). He saw the industrialisation process as the logical dialectical progression of feudal economic modes, necessary for the full development of capitalism, which he saw as in itself a necessary precursor to the development of socialism and eventually communism.

Romantic Movement

Concurrent with the Industrial Revolution there developed an intellectual and artistic hostility towards the new industrialisation known as the Romantic Movement. Its major exponents in English included the artist and poet William Blake and poets William Wordsworth, Samuel Taylor Coleridge, John Keats, Byron and Percy Bysshe Shelley. The movement stressed the importance of "nature" in art and language, in contrast to the 'monstrous' machines and factories. In Blake's words they were the, "Dark satanic mills" of his poem And did those feet in ancient time. Mary Shelley's novel Frankenstein reflected a concern about the possibly two-edged nature of scientific progress.

Second Industrial Revolution

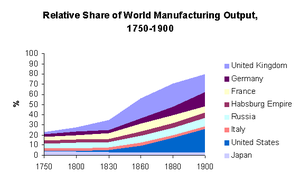

The insatiable demand of the railways for more durable rail led to the development of the means to cheaply mass-produce steel. Steel is often cited as the first of several new areas for industrial mass-production, which are said to characterize a "Second Industrial Revolution", beginning around 1850. This second Industrial Revolution gradually grew to include the chemical industries, petroleum refining and distribution, electrical industries, and, in the twentieth century, the automotive industries, and was marked by a transition of technological leadership from Britain to the United States and Germany.

The introduction of hydroelectric power generation in the Alps enabled the rapid industrialisation of coal-deprived northern Italy, beginning in the 1890s. The increasing availability of economical petroleum products also reduced the importance of coal and further widened the potential for industrialisation.

By the 1890s, industrialisation in these areas had created the first giant industrial corporations with burgeoning global interests, as companies like U.S. Steel, General Electric, and Bayer AG joined the railroad companies on the world's stock markets.