Domestic AC power plugs and sockets

2007 Schools Wikipedia Selection. Related subjects: Engineering

-

This article covers only plugs and sockets intended for common domestic use. For plugs and sockets used for industrial applications, or with more than two current carrying conductors, see Industrial & multiphase power plugs & sockets. For less common plugs and sockets see unusual and obsolete plugs and sockets.

Domestic AC power plugs and sockets are devices that connect the home appliances and portable light fixtures commonly used in homes to the commercial power supply so that AC electric power can flow to them.

Power plugs are male electrical connectors that fit into female electrical sockets. They have contacts that are pins or blades which connect mechanically and electrically to holes or slots in the socket. Plugs usually have a live or hot contact, a neutral contact, and an optional earth or ground contact. Many plugs make no distinction between the live and neutral contacts, and in some cases they have two live contacts. The contacts may be brass, tin or nickel plated.

Power sockets are female electrical connectors that have slots or holes which accept the pins or blades of power plugs inserted into them and deliver electricity to the plugs. Sockets are usually designed to reject any plug which is not built to the same electrical standard. Some sockets have one or more pins that connect to holes in the plug.

| Standard wire colours for flexible cable | |||

|---|---|---|---|

| Region | Live | Neutral | Protective earth |

| EU, Australia & South Africa ( IEC 60446) | brown | blue | green & yellow |

| UK, Ireland & Australia before 1969 | red | black | green |

| United States and Canada (screw colour) | black (brass) | white (silver) | green (green) |

| Standard wire colours for fixed cable | |||

| Region | Live | Neutral | Protective earth |

| EU ( IEC 60446) including UK from 31 March 2004 | brown or black | blue | green & yellow |

| UK before 1 April 2006 & Australia | red | black | green & yellow (core is usually bare and should be sleeved at terminations) |

| United States and Canada (screw colour) | black or red (brass) | white (silver) | green or bare (green) |

| Note: the colours in this table represent the most common and preferred standard colours however others may be in use, especially in older installations. | |||

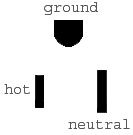

The three contacts

In most countries, household power is single-phase electric power, in which a single live conductor brings alternating current into a house, and a neutral returns it to the power supply. Many plugs and sockets include a third contact used for a protective earth ground, which only carries current in case of a fault in the connected equipment.

Live or Phase

The live contact (also known as phase, hot or active) carries alternating current from the power source to the equipment. The voltage varies by country, as set by national standards. In some installations, there may be two live conductors, either being two phases from a three-phase system or being both phases from a split phase system. Some plug/socket combinations are designed in a way that a plug can be inserted only one possible way — this is referred to as a polarized plug (not to be confused with positive and negative polarity). Others allow the plug to be inserted with live and neutral either way round — this is referred to as an unpolarized plug. Furthermore even if live and neutral can only connect one way, in some countries it is common to wire them without regard for which is which. This can be hazardous with some equipment in which the neutral is connected directly to the chassis.

Neutral

The neutral contact returns current from the equipment back to the power source or distribution panel. It is in most (but not all) cases referenced to the earth. Except under fault conditions it does not pose a danger because the voltage between the neutral contact and the earth is close to zero, but is nevertheless treated as live in most installation practices because it can develop a high voltage under fault conditions.

The main danger posed by the neutral is the voltage can rise as high as the voltage on the live conductor if a broken neutral cable in the wiring disconnects the neutral but leaves the live conductor connected. Another possibility is that the live and neutral may be reversed or crossed by improper installation.

Neutral and earth (ground) are closely related and are usually connected at some point. However extra connections between the neutral and the earth should be avoided unless the relevant jurisdiction's regulations allow it. Connecting neutral and earth at more than one point can sometimes create a dangerous ground loop in the system.

Earth/Ground

The earth contact (known as ground in American English) is only intended to carry electric current when connected to equipment that has developed an insulation fault (except for EMI/RFI filters which do cause a small current down the earth). The earth connection was added to modern plugs because, if a live wire or other component in a device touches the metal casing, anybody touching the device may receive a dangerous electric shock. In many countries devices with metal cases must have the case connected to the earth contact. This reduces but does not eliminate the possibility of the case developing a high voltage relative to the earth and grounded metalwork.

It is a common misconception that the purpose of the earth connection is to take fault currents safely to earth. The primary purpose of the earthing system is to cause a fuse to blow or a breaker or a residual-current device (RCD) to trip to automatically disconnect the power supply to any device or cable which develops a wiring fault. The secondary purpose is to hold all touchable metal in a house to the same voltage to prevent electrical shocks when touching two metal objects at the same time.

There are two main approaches to the problem of how to disconnect power when a live wire comes into contact with metalwork attached to the earthing system. One way is to get the resistance through the fault path and back to the supply very low by having a metallic connection from the earth back to the supply transformer (a TN system). Then when a fault happens a very high current will flow rapidly blowing a fuse (or tripping a MCB).

Where such a direct connection is not used (a TT system) the resistance of the fault path back to the supply is almost invariably far higher and as a result the fault current is generally too low to reliably blow fuses (or trip MCBs). Therefore an RCD must normally be used to disconnect the fault.

The neutral core could in theory be used as a ground, but this would be dangerous if the core broke, so this is not normally used in building wiring or portable appliances. It is, however, used in some other situations with special precautions. For instance, in Switzerland, sockets in houses with the old two wire installation have the ground and neutral contacts connected together, probably supposing, that the professionally maintained house installation is much more reliable than plugged-in device. Also using the neutral as a ground prevents the use of RCDs.

Differences in terminology

There are significant differences between American English and British English in talking about power plugs and sockets.

| British | American | Meaning |

|---|---|---|

| mains power | line power | House electrical AC current |

| earth connection | ground connection | Safety connection to the earth or ground |

| flex | cord | Flexible electric cable from plug to appliance |

| socket, power point | outlet, receptacle | Female part of an electrical connection |

| pin | prong | Male part of an electrical connector |

In the United States, the live contact may be called live or hot. The neutral contact may be called cold, neutral, the grounded conductor, or (in the National Electrical Code), the identified conductor. The earth contact is called ground or the grounding conductor.

In the United Kingdom the word "line" is occasionally used to denote the live terminal or wire. This terminology derives from its being at the line voltage relative to neutral and ground, as distinct from the "phase" voltage, between lines on different phases of the supply.

Live conductors are called phases when there is more than a single phase in use. Pins are also known as prongs, contacts or terminals.

In Australia, the live contact is called active.

History of plugs and sockets

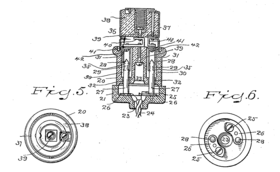

When electricity was first introduced into the household, it was primarily used for lighting. At that time, many electricity companies operated a split-tariff system where the cost of electricity for lighting was lower than that for other purposes. This led to low-power appliances (such as vacuum cleaners and hair driers) being connected to the light fitting. The picture to the right shows a 1909 electric toaster with a light bulb socket plug.

However, as electricity became a common method of heating houses and operating labour-saving appliances, a means of connection to the electric system other than using a light socket was needed. The original two prong electrical plug and socket were invented by Harvey Hubbell and patented in 1904.

The three prong plug was invented in 1928 by Philip F. Labre, while he was going to school at the Milwaukee School of Engineering (MSOE). It is said that his landlady had a cat which would knock over her fan when it came in the window. When she plugged the fan back in, she would get an electric shock. Philip figured out that if the plug was grounded, the electricity would go to earth through the plug rather than his landlady. He applied for and was issued a patent for grounding receptacle and plug on June 5, 1928. As the need for safer installations became apparent, earthed three-contact systems were made mandatory in most industrial countries.

Proliferation of standards

The reason that there are now over a dozen different styles of plugs and wall outlets is that when European countries adopted 220-240V electricity, for nationalistic reasons they developed their own unique national plug designs instead of agreeing on a European standard plug. In contrast, the 38 different countries which adopted the American 110-120V standard electricity also adopted the U.S. type A and B plugs. Most countries elsewhere in the world were once colonies of European nations and usually adopted the standards of their colonial governments at the time electricity was introduced. In many other countries there is no single national standard and multiple voltages, frequencies and plug designs are in use, creating extra complexity and potential safety problems for users.

However, in recent years most countries have settled on one of a few de facto standards, although there are legacy installations of obsolete wiring in most countries of the world. Some buildings have wiring that has been in use for almost a century and which pre-dates all modern standards.

To minimize the difficulty of designing for different national standards, many manufacturers of electrical devices like personal computers have adopted the practice of putting a single world-standard IEC connector on the device, and supplying for each country a power cord equipped with a standard IEC connector on one end and a national power plug at the other. The device itself is designed to adapt to a wide range of voltage and frequency standards.

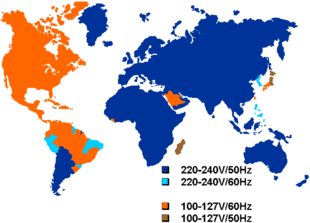

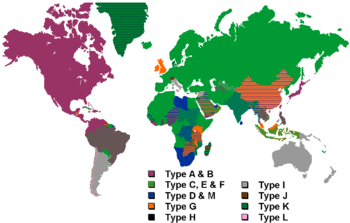

World maps by plug/socket and voltage/frequency

There are two basic standards for voltage and frequency in the world. One is the North American standard of 110-120 volts at 60 Hz, which uses plugs A and B, and the other is the European standard of 220-240 volts at 50 Hz, which uses plugs C through M. The differences arose for historical reasons.

In the United States, Thomas Edison, the inventor of the first practical electric light bulb, insisted on using 110 volts direct current (DC) rather than alternating current (AC) for his electric system in New York City. However, George Westinghouse, who built the first large hydro-electric plants at Niagara Falls, decided to use AC instead of DC because it could be stepped up or stepped down in voltage using transformers. The electrical genius Nicola Tesla advised him that 240 V at 60 Hz was optimum, but authorities would not let him use more than 110 V for distribution. Eventually Edison switched his 110 V DC system over to AC as well, and so 110 V at 60 Hz became the American electrical standard, despite the fact it required conductors twice as large to carry the same amount of power as 240 V.

In Europe, the German company AEG built the first generating facilities, and chose 50 Hz because it fit better into the metric system of powers of ten (1, 10, 100). Unfortunately, 50 Hz is less efficient than 60 Hz because generators are 20% less efficient and transformers must be 30% bigger to step the voltage up and down. However, AEG had a virtual monopoly in Europe so their standard spread to the rest of the continent and eventually to Britain. Originally Europe was electrified at 110-120 V like North America, but after World War II, regulators decided to increase it to 220-240 V to reduce the amount of copper used for wiring.

American regulators would have liked to double the voltage as well, but there were far more household electrical appliances than in Europe. They compromised by adopting a split phase 240 V system, supplying 120 V on two live conductors going into each household with a single neutral. Small appliances ran on 120 V, big ones on 240 V. It was more complicated but saved copper and was backward-compatible with existing appliances. The original plugs could be used with the system, as well.

Countries on other continents have adopted one of these two voltage standards, although some countries use variations or a mixture of standards. The outline maps below show the different plug types, voltages and frequencies used around the world, colour-coded for easy reference.

See also List of countries with mains power plugs, voltages and frequencies for specific places.

Types of plug and sockets

Electrical plugs and their sockets differ by country in shape, size, and type of connectors. The type used in each country is set by national standards legislation. In this article each type is designated by a letter, plus a short comment in parentheses giving its country of origin and number of contacts. Subsections then detail the subtypes of each type as used in different parts of the world.

Note that IEC Class I refers to earthed equipment. IEC Class II refers to unearthed equipment protected by double insulation. See Appliance classes.

Type A (North American/Japanese 2-pin)

- NEMA 1-15 (North American 15 A/125 V ungrounded)

Standardized by the U.S. National Electrical Manufacturers Association and adopted by 38 other countries, this simple plug with two flat parallel pins, or blades, is used in most of North America and on the west coast of South America on devices not requiring a ground connection, such as lamps and "double-insulated" small appliances. NEMA 1-15 sockets have been prohibited in new construction in the United States and Canada since 1965, but remain in many older homes and are still sold "for replacement use only". Type A plugs are still very common because they are compatible with type B sockets.

Early designs could be inserted either way, but modern ones prevent the neutral pin from being inserted into the live socket by making it wider than the live one, referred to as a polarized plug. (Note that this is not the same as positive/negative polarization in a direct current system.) New polarized plugs will not fit in old type A sockets, but both old and new type A plugs will fit in new type A and type B sockets. Some devices that do not distinguish between neutral and live, such as sealed electronic power supplies, are still sold with both pins narrow. When attaching a new polarized plug to a cord, it is useful to remember that the most common type of two-conductor cord for low-power use in North America has smooth insulation on the "hot" side and ribbed insulation on the "neutral" side.

- JIS 8303, Class II (Japanese 15 A/100 V ungrounded)

The Japanese plug and socket are identical to NEMA 1-15. However, the Japanese system incorporates stricter dimensional requirements for the plug housing, different marking requirements, and mandatory testing and approval by MITI or JIS.

Some Japanese outlets are non-polarized — the slots in the sockets are the same size - and will only accept non-polarized plugs. Japanese plugs should be able to fit into North American outlets without trouble, but North American appliances with polarized plugs may require adapters or replacement non-polarized plugs to connect to Japanese outlets.

Japanese standard wire sizes and the resulting current ratings are somewhat different from those used elsewhere in the world. Japanese voltage is only 100 volts - lower than American voltage - and the frequency in eastern Japan is only 50 hertz instead of 60, so even if a North American plug can be inserted into a Japanese socket, it does not always mean the device will work properly.

Type B (American 3-pin)

- NEMA 5-15 (North American 15 A/125 V grounded)

The type B plug has two flat parallel blades like type A, but has a round ground or earthing pin (American standard NEMA 5-15/Canadian standard CSA 22.2, Nº42). It is rated for 15 amps at 125 volts. The ground pin is longer than the live and neutral blades, so the device is grounded before the power is connected. The neutral blade in the type B socket is wider than the live one to prevent type A plugs being inserted upside-down, but type B plugs often have both pins narrow since the ground pin enforces polarity.

The 5-15 socket is standard in all of North America (Canada, the United States and Mexico). It is also used in Central America, the Caribbean, the west coast of South America, Japan, parts of Korea, and Taiwan.

With type B plugs, if you look directly at a socket with the ground socket at a bottom, the neutral slot is on the left, and the live slot is on the right. They may also be installed with the ground at the top or on either side, but the sockets going clockwise are always ground, neutral, live. The plug has the same connections going counterclockwise. If the plug is polarized, the widest pin is the neutral connector.

Due to the low power (1.8KW) available from a 120V 15A socket a number of other NEMA connector for higher currents and 240 V supplies are also commonly encountered in North American homes.

- JIS 8303, Class I (Japanese 15 A/100 V grounded)

Japan also uses a Type B plug similar to the North American one. However it is less common than its Type A equivalent.

Type C (European 2-pin)

- CEE 7/16 (Europlug 2.5 A/250 V unearthed)

This two-pin plug is probably the single most widely used international plug, popularly known as the Europlug. The plug is unearthed and has two round, 4 mm pins, which usually converge slightly. It can be inserted into any socket that accepts 4 mm round contacts spaced 19 mm apart. It is described in CEE 7/16. and is also defined in Italian standard CEI 23-5 and Russian standard GOST 7396

The Europlug is used in Class II applications throughout continental Europe (Germany, Austria, Switzerland, Italy, Greece, the Netherlands, Belgium, France, Spain, Portugal, Denmark, Norway, Sweden, Finland, Poland, The Czech Republic, Slovakia, Hungary, Romania, Bulgaria). It is also used in Turkey, the Middle East, most of Africa and South America (Brazil), as well as the former Soviet republics, and many developing nations.

This plug is intended for use with devices that require 2.5 A or less. Because it can be inserted in either direction into the socket, live and neutral are connected at random.

- CEE 7/17 (German/French 16 A/250 V unearthed)

This plug also has two round pins but the pins are 4.8 mm in diameter like types E and F and the plug has a round plastic or rubber base that stops it being inserted into small sockets intended for the Europlug. Instead, it fits only into large round sockets intended for types E and F. The base has holes in it to accommodate both side contacts and socket earth pins. It is used for large Class II appliances. Often used in South Korea, it is also defined in Italian standard CEI 23-5.

- BS 4573 (UK shaver)

In the United Kingdom and Ireland, there is a special version of the type C plug for use with shavers (electric razors) in bath or shower rooms. It has 5 mm diameter pins 16.6 mm apart, and the sockets for this plug can often take CEE 7/16, US and/or Australian plugs as well. Sockets are often able to supply either 230 V or 115 V. In wet zones, they must contain an isolation transformer compliant with BS 3535.

- Variations in sockets

Some Type C sockets can only take 4 mm pins or have plastic barriers in place to prevent Schuko or French plugs from entering. However, many can take 4.8 mm pins and have enough room for a 4.8 mm pin round Schuko or French plug to be inserted.

Type D (Old British 3-pin)

- BS 546 (Indian 5 A/250 V earthed)

India has standardised on a plug which was originally defined in British standard BS 546. It has three large round pins in a triangular pattern. The BS 546 standard is also used in parts of Africa (Ghana, Kenya, Nigeria), the Middle East (Kuwait, Qatar), and parts of Asia and the Far East that were electrified by the British. This type was also previously used in South Africa, but has been phased out in favour of the 15 A version there. This 5 A plug, along with its 2 A cousin, is sometimes used in the UK for centrally switched domestic lighting circuits, in order to distinguish them from normal power circuits.

- BS 546 (South African 15 A/250 V earthed)

This plug is sometimes referred to as type M, but it is in fact merely the 15 A version of the plug above, though its pins are much larger at 7.05 mm × 21.1 mm. Live and neutral are spaced 25.4 mm apart, and earth is 28.6 mm away from each of them. Although the 5 A version is standard in India, Sri Lanka, Nepal, and Namibia, the 15 A version is also used in these countries for larger appliances. Some countries like South Africa use it as the main domestic plug and socket type, where sockets almost always have an on–off switch built into them. The Type M is almost universally used in the UK for indoor dimmable theatre and architectural lighting installations. It is also often used for non-dimmed but centrally controlled sockets within such installations. The main reason for doing this is that fused plugs, while convenient for domestic wiring (as they allow 32 A socket circuits to be used safely), are not convenient if the plugs and sockets are in hard to access locations (like lighting bars) or if using chains of extension leads (since it is hard to figure out which fuse has blown). Both of these situations are common in theatre wiring. This plug is also widely used in Israel for air conditioners.

Type E (French 2-pin, female earth)

- French type E

France, Belgium, Poland, Czech Republic, Slovakia and some other countries have standardised on a socket which is not compatible with the CEE 7/4 socket (type F) that is standard in Germany and other continental European countries. The reason for incompatibility is that earthing in the E socket is accomplished with a round male pin permanently mounted in the socket. Sockets are installed with the earth pin upwards and wired with left as live and right as neutral. The plug itself is round with two round pins measuring 4.8 × 19 mm, spaced 19 mm apart and a hole for the socket's earth pin. It will accept Europlug and CEE 7/17 plugs.

As with the German plug below this plug will fit some other types of socket either easily or with force. However there is no earth connection with such sockets! Also in some cases if the plug is forced in, the socket may be damaged when the plug is removed.

Type F (German 2-pin, side clip earth)

- CEE 7/4 (German "Schuko" 16 A/250 V earthed)

The type F plug, defined in CEE 7/4 and commonly called a " Schuko plug", is like type E except that it has two earthing clips on the sides of the plug instead of a female earth contact. The Schuko connection system is symmetrical and allows live and neutral to be reversed. The socket also accepts Europlugs and CEE 7/17 plugs. It supplies up to 16 amperes. Above that, equipment must either be wired permanently to the mains or connected via another higher power connector such as the IEC 309 system.

"Schuko" is an abbreviation for the German word Schutzkontakt, which means "Protective (that is, earthed) contact".

- Gost 7396 (Russian 16 A/250 V earthed)

The countries of the CIS use a standard plug and socket similar to the Schuko standard, defined in Russian Standard Gost 7396. The contacts are also 19 mm apart, but the diameter of the pins is 4.0 mm instead of 4.8 mm. It is possible to insert Russian plugs into Schuko outlets, but Russian sockets will not accept type E or F plugs because the holes are too small. This socket also accepts Europlugs, but does not accept CEE 7/17 plugs because they use the larger pin size.

Many official standards in Eastern Europe are virtually identical to the Schuko standard. One of the protocols governing the reunification of Germany required that the DIN and VDE standards would prevail without exception, so the former East Germany had to conform to the Schuko standard. Most other Eastern European countries use the Schuko standard internally but, prior to its collapse, they exported large volumes of appliances to the Soviet Union with the Soviet standard plug installed. Because of that, many of the Russian plugs found their way into other Eastern European countries.

Type E and F hybrid

- CEE 7/7 (French/German 16 A/250 V earthed)

In order to bridge the differences between sockets E and F, the CEE 7/7 plug was developed. It has earthing clips on both sides to connect with the CEE 7/4 socket and a female contact to accept the earthing pin of the type E socket. Nowadays, when appliances are sold with type E/F plugs attached, the plugs are CEE 7/7 and non-rewirable. This means that the plugs are now identical between countries like France and Germany; only the sockets are different.

Type E and F plugs that are not compatible with both types of socket are only found if a cheap replacement plug has been attached to a cord that originally had another plug. Better-quality replacements are standard CEE 7/7 and are compatible with both Schuko and French standard sockets.

Note that the CEE 7/7 plug is polarized to prevent the live and neutral connections from being reversed when used with a type E outlet, but allows polarity reversal when inserted into a type F socket. The plug is rated at 16 A. Above that, equipment must either be wired permanently to the mains or connected via another higher power connector such as the IEC 309 system.

Type G (British 3-pin)

- BS 1363 (British 13 A/250 V earthed and fused)

The BS 1363 plug, commonly known as a "13-amp plug", is a large plug that has three rectangular prongs forming a triangle. Live and neutral are 4 × 6 × 18 mm spaced 22 mm apart. 9 mm of insulation over the base of the pins prevents people from touching a bare connector while the plug is partly inserted. Earth is 4 × 8 × 23 mm.

The plug is unusual in that it has a fuse inside, for protection, in addition to a circuit breaker in the distribution panel. The fuse is required to protect the flex, as British wiring standards allow very high-current circuits to the socket. Accepted practice is to choose the smallest standard fuse (3 A, 5 A, or 13 A) that will allow the appliance to function. Using a 13 A fuse on an appliance with thin flex is considered bad practice.

The earth pin is required to open shutters over the live and neutral pins on most sockets to prevent children from inserting metal objects into them, and also prevents the use of plugs made to other standards. On plugs for Class II appliances that do not require an earth, the pin is often plastic. It is possible to open the shutters with a screwdriver to insert other plug types but this should be avoided as such plugs will not have a fuse.

BS 1363 was published in 1962 and since that time it has gradually replaced the earlier standard (type D) ( BS 546). Despite being capable of carrying a maximum load of 13 A, it is considered a very safe system.

Type H (Israeli 3-pin)

- SI 32 (Israeli 16 A/250 V earthed)

This plug, defined in SI 32 (IS16A-R), is unique to Israel and is incompatible with all other sockets. It has three flat pins to form a Y-shape. "Live" and "Neutral" are spaced 19 mm apart. The type H plug is rated at 16 A but in practice the inadequate flat pins cause it to overheat when connecting large appliances. In 1989 the SI 32 was revised to use three round 4 mm pins in the same locations as the older standard. Sockets are manufactured to accept both flat and round pins in order to be compatible with both old and new plugs. This also allows the type H socket to accommodate type C plugs which are used in Israel for non grounded appliances. Older sockets, from about the 1970s have both flat and round holes for "Live" and "Neutral" in order to accept type C plugs. As of 2006, "pure" type H sockets (for 3 flat pins) that do not accept type C plugs are very rare in Israel.

This plug is also used in the areas controlled by the Palestinian National Authority in the West Bank and all of the Gaza Strip.

Type I (Australian/Chinese 2/3-pin)

- AS 3112 (Australian 10 A/250 V)

This plug, used in Australia, New Zealand, and Papua New Guinea, has an earthing pin and two flat pins forming an upside down V-shape. There is an unearthed version of this plug as well, with no earthing pin. The flat blades measure 6.5 × 1.6 mm and are set 30° to the vertical on a nominal pitch of 13.7 mm. Australian wall sockets almost always have switches on them for extra safety, as in the UK.

There are several AS/NZS 3112 plug variants, including one with a wider earth pin is used for devices drawing up to 15 A; sockets supporting this pin will also accept 10 A plugs. Additionally, there exists a 20 A variant, in which all three pins are oversized and 25 and 32 A variants with the 20 A larger pins and the earthing pin forming an inverted "L" for the 25 A and a horizontal "U" for the 32 A (note that the 5 variants {10; 15; 20; 25 & 32 ampere sockets} will accommodate all the plugs that are equal or of a lesser current carring capacity but not a higher value; i.e. a 10 A plug will be accommodated by all sockets but a 20 A plug will only be accommodated by a 20: 25 and 32 A outlet).

Australia's standard plug/socket system was originally codified as standard C112 (floated provisionally in 1937, and adopted as a formal standard in 1938), which was superseded by AS 3112 in 1990. As of 2005, the latest major update is AS/NZS 3112:2004, which mandated insulated pins by 2005. However, equipment and cords made before 2003 can still be used.

- CPCS-CCC (Chinese 10 A/250 V)

Although the Chinese plug is slightly different (the pins are 1 mm longer) the Australian plug can be inserted into the socket used in the mainland China. The standard for Chinese plugs and sockets was set out in GB 2099.1–1996 and GB 1002–1996. As part of China's commitment for entry into the WTO, the new CPCS (Compulsory Product Certification System) has been introduced, and compliant Chinese plugs have been awarded the CCC (China Compulsory Certification) Mark by this system. The plug is three wire, grounded, rated at 10 A, 250 V and used for Class 1 applications.

In China, the sockets are installed upside down, relative to the Australian one shown in the picture. However, the positions of the live and neutral contacts are reversed from those of the Australian plug. With devices conforming to current standards this is not too serious, as neutral is generally treated the same as live in appliance design. However with older or non-complying equipment this difference can be dangerous.

China also uses American/Japanese "Type A" sockets and plugs for Class-II appliances. However, the voltage across the pins of a Chinese socket will always be 220, no matter what the plug type.

- IRAM 2073 (Argentinian 10 A/250 V)

The Argentinian plug is a three-wire, earthed plug rated at 10 A, 250 V defined by IRAM and used in Class 1 applications in Argentina and Uruguay.

This plug is similar in appearance to the Australian and Chinese plugs. The pin lengths and wiring are the same as those for the Chinese version. The most important difference from the Australian plug is that the Argentinian plug is wired with the live and neutral contacts reversed from those of the Australian plug.

Type J (Swiss 3-pin)

- SEV 1011 (Swiss 10 A/250 V)

Switzerland has its own standard which is described in SEV 1011. (ASE1011/1959 SW10A-R) This plug is similar to the type C europlug (CEE 7/16), except that it has an earth pin off to one side. Swiss sockets can take Swiss plugs or europlugs (CEE 7/16). This connector system is rated for up to 10 amperes. There is also a less common variant with 3 square pins rated for 16 A. Above 16 A, equipment must either be wired permanently to the electrical supply system with appropriate branch circuit protection, or connected to the mains with an appropriate high power industrial connector.

Switzerland also has a two-pin plug, with the same pin shape, size and spacing as the SEV 1011's live and neutral pins, but with a more flattened hexagonal form. It fits into both Swiss sockets (round and hexagonal) and CEE 7/16 sockets, and is rated for up to 10 A.

- IEC 60906-1 (Brazilian 16 A/250 V)

In 1986, the International Electrotechnical Commission published IEC 60906-1, the specification for a plug that looks similar but is not identical to the Swiss plug. This plug was intended to become one day the common standard for all of Europe and other regions with 230 V mains but the effort to adopt it as a European Union standard was put on hold in the mid 1990s. Brazil — which uses a mix of Europlug, Argentine and NEMA plugs — later adopted it as national standard NBR 14136 in 2001 and it will be the only plug permitted to be sold with domestic appliances in Brazil from 2009.

Type K (Danish 3-pin)

- DS Afsnit 107-2-D1 (Danish 10 A/250 V)

The Danish standard plug is described in DS section 107-2-D1 (SRAF1962/DB 16/87 DN10A-R). The plug is similar to the type F Schuko plug except that it has an earthing pin instead of earthing clips. The Danish socket will also accept the type C CEE 7/16 Europlug or type E/F CEE 7/17 Schuko-French hybrid plug. Type F CEE 7/4 (Schuko), type E/F CEE 7/7 (Schuko-French hybrid), and earthed type E French plugs will also fit in the socket but should not be used because the earth contact will not connect. A variation of this plug intended for use only on surge protected computer circuits has been introduced. The current rating on both plugs is 10 A.

Adapter plugs exist to allow connection of CEE 7/7 prongs to non-computer outlets. These usually are not sold at the local supermarket so visitors wishing to be safe should contact an electrician.

Since the early 1990s grounded outlets have been required in all new electric installations in Denmark.

Type L (Italian 3-pin)

The Italian earthed plug/socket standard, CEI 23-16/VII, includes two models rated at 10 A and 16 A that differ in contact diameter and spacing. Both are symmetrical, allowing the live and neutral contacts to be inserted in either direction. CEE 7/16 (type C) unearthed Europlugs are also in common use, and standardized in Italy as CEI 23-5. Appliances with CEE 7/7 Schuko-French plugs are often sold in Italy, but not every socket will accept them. Adapters are commonly used to connect CEE 7/7 plugs to CEI 23-16/VII sockets.

- CEI 23-16/VII (Italian 10 A/250 V)

The 10 ampere style extends CEE 7/16 by adding a central earthing pin. Thus, CEI 23-16-VII 10 A sockets can accept CEE 7/16 Europlugs. This is the plug shown in the illustrations. Outside of Italy, this plug is found in Libya, Ethiopia, Chile, various countries in North Africa, and occasionally in old buildings in Spain.

- CEI 23-16/VII (Italian 16 A/250 V)

The 16 ampere style looks like a bigger version of the 10 A style. The pins are a couple of millimetres further apart, and all three are slightly thicker. The packaging on these plugs in Italy may claim they are a "North European" type. They were also referred to as industriale ("industrial") although this is not a correct definition.

- Variations in sockets

Two types of sockets are in common use in modern installations in Italy. One type has a central round hole and two 8-shaped holes above and below. This design allows the connection of both styles of type L plugs (CEI 23-16/VII 10 A and 16 A) and the type C CEE 7/16 Europlug. The advantage of this socket type is its small footprint.

The other type looks like a type F socket, but adds a central grounding hole. This design accepts CEE 7/7 (type E/F) plugs, in addition to type C and type L 10 A plugs; its disadvantage is that it is twice as large as a normal type L socket. Some of these sockets also have extra holes to accept type L 16 A plugs.

Older installations often have sockets that are limited to either the 10 A or the 16 A style plug, requiring the use of an adapter if the other style needs to be connected.

Type M (see D)

- BS 546 (South African 15 A/250 V)

Type M is sometimes used to describe the 15 A version of the old British type D, used in South Africa and elsewhere. See type D for details.

Multi standard sockets

Sockets that take a variety of incompatible plug types are often seen in developing countries where electrical standards are either lacking or unenforced. These sockets may accept both 120 V and 240 V plugs raising a significant risk of devices being be damaged by the wrong voltage. Sometimes they have one or more earth holes to allow 3 pin plugs, but there is a good chance that the ground contact may not actually be connected to earth and the ground contact certainly will not mate with schuko or french plugs. Great care should be taken to avoid incompatible voltage and grounding connections when using such outlets. Multi-standard devices designed to auto-adapt to different voltage and frequency standards, and which do not require a ground contact are best used with these sockets.