Stock car (rail)

2007 Schools Wikipedia Selection. Related subjects: Railway transport

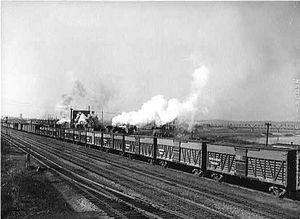

In railroad terminology, a stock car is a type of rolling stock used for carrying livestock (not carcasses) to market. A traditional stock car resembles a boxcar with slats missing in the car's side, and sometimes end, panels for ventilation; stock cars can be single-level for large animals such as cattle or horses, or they can have two or three levels for smaller animals such as sheep, pigs, and poultry. Specialized types of stock cars have been built to haul live fish and shellfish and circus animals such as camels and elephants. Until the 1880s, when the Mather Stock Car Company and others introduced "more humane" stock cars, loss rates could be quite high as the animals were hauled over long distances. Improved technology and faster shipping times have greatly reduced losses.

Initial use and development

Rail cars have been used to transport livestock since the 1830s. The first shipments in the United States were made via the B&O Railroad in general purpose, open-topped cars with semi-open sides. Thereafter, and until 1860, the majority of shipments were made in conventional boxcars that had been fitted with open-structured iron-barred doors for ventilation. Some railroads constructed "combination" cars that could be utilized for carrying both live animals as well as conventional freight loads.

Getting food animals to market required herds to be driven distances of hundreds of miles to railheads in the Midwest, whereupon they were loaded into stock cars and transported eastward to regional processing centers. Driving cattle across the plains led to tremendous weight loss, and a number of animals were typically lost along the way. Upon arrival at the local processing plant, livestock were either slaughtered by wholesalers and delivered fresh to nearby butcher shops for retail sale, smoked, or packed for shipment in barrels of salt.

The suffering of animals in transit as a result of hunger, thirst, and injury were considered by many to be inherent to the shipping process, as were the inevitable loss of weight during shipment. A certain percentage of animal deaths on the way to market was even considered normal (6% for cattle and 9% for sheep on average, according to a congressional inquiry), and carcasses of dead animals were often disposed of along the tracks to be devoured by scavengers, though some were sold to glue factories or unscrupulous butchers. Increased train speeds reduced overall transit times, though not enough to offset the deleterious conditions the animals were forced to endure.

When the railroads and cattle industry failed to act quickly enough to correct these perceived deficiencies, the government and even the general public went into action. Claims were made that the meat of neglected animals was unfit for human consumption. In 1869, Illinois passed the first laws requiring that limited the animals' time on board, and required them to be given 5 hours' rest for every 28 in transit. Other states such as Ohio and Massachusetts soon followed with similar legislation, though effective federal laws would not be enacted until the passing of the Federal Meat Inspection Act of 1906.

Alonzo Mather, a Chicago clothing merchant who founded the Mather Stock Car Company, designed a new stock car in 1880 that was among the first to include amenities for feeding and watering the animals while en route. Mather was awarded a gold medal in 1883 by the American Humane Association for the humane treatment afforded to animals in his stock cars. Minneapolis' Henry C. Hicks patented a convertible boxcar/stock car in 1881, which was improved in 1890 with features that included a removable double deck. George D. Burton of Boston introduced his version of the humane stock car in 1882, which was placed into service the following year. The Burton Stock Car Company's design provided sufficient space so as to allow the animals to lie down in transit on a bed of straw.

Certain costly inefficiencies were inherent in the process of transporting live animals by rail, particularly due to the fact that some sixty percent of the animal's mass is composed of inedible matter. And even after the humane advances cited above were put into common practice, many animals weakened by the long drive died in transit, further increasing the per-unit shipping cost. The ultimate solution to these problems was to devise a method to ship dressed meats from regional packing plants to the East Coast markets in the form of a refrigerated boxcar.

The advent of the refrigerator car

A number of attempts were made during the mid- 1800s to ship agricultural products via rail car. In 1857, the first consignment of dressed beef was carried in ordinary boxcars retrofitted with bins filled with ice. Detroit's William Davis patented a refrigerator car that employed metal racks to suspend the carcasses above a frozen mixture of ice and salt. He sold the design in 1868 to George Hammond, a Chicago meat-packer, who built a set of cars to transport his products to Boston.

In 1878, meat packer Gustavus Swift hired engineer Andrew Chase to design a ventilated car, one that proved to be a practical solution to providing temperature-controlled carriage of dressed meats, and allowed Swift & Company to ship their products all over the United States, and even internationally. The refrigerator car radically altered the meat business. Swift's attempts to sell Chase's design to the major railroads were unanimously rebuffed, as the companies feared that they would jeopardize their considerable investments in stock cars, animal pens, and feedlots if refrigerated meat transport gained wide acceptance.

In response, Swift financed the initial production run on his own, then — when the American roads refused his business — he contracted with the Grand Trunk Railway (who derived little income from transporting live cattle) to haul the cars into Michigan and then eastward through Canada. In 1880 the Peninsular Car Company (subsequently purchased by ACF) delivered to Swift the first of these units, and the Swift Refrigerator Line (SRL) was created. Within a year the Line's roster had risen to nearly 200 units, and Swift was transporting an average of 3,000 carcasses a week to Boston. Competing firms such as Armour and Company quickly followed suit.

Live cattle and dressed beef deliveries to New York ( tons):

| (Stock Cars) | (Refrigerator Cars) | |

| Year | Live Cattle | Dressed Beef |

| 1882 | 366,487 | 2,633 |

| 1883 | 392,095 | 16,365 |

| 1884 | 328,220 | 34,956 |

| 1885 | 337,820 | 53,344 |

| 1886 | 280,184 | 69,769 |

The subject cars travelled on the Erie, Lackawanna, New York Central, and Pennsylvania railroads.

Source: Railway Review, January 29, 1887, p. 62.

Specialized applications

Horse cars

For many decades, racehorse owners regarded the railway as the quickest, cheapest, safest, and most efficient medium of equine transport. The horse express car allowed the animals (in some instances) to leave home the morning of a race, theoretically reducing stress and fatigue.

As early as 1833 in England, specially-padded boxcars equipped with feeding and water apparatus were constructed specifically for transporting draft and sport horses. In the United States, however, horses generally traveled in conventional stock cars or ventilated boxcars. Early on, the need for improved methods for tethering horses in boxcars, while at the same time allowing a horse enough room to maintain its balance while in transit, was recognized.

Racehorses, and those kept as breeding stock, were highly-valued animals that required special handling. In 1885 a livery and stable operator from Toledo, Ohio by the name of Harrison Arms formed the Arms Palace Horse Car Company to service this market niche. Arms' cars resembled the passenger cars of the day; they featured clerestory roofs and end platforms and came equipped with passenger car trucks (as they were intended for passenger train service). The units were segregated into two separate compartments, each containing eight individual stalls. By the late 1880s Arms had acquired two competing firms, Burton and Keystone. While the cars operated by George D. Burton closely resembled the Arms design, the Keystone Company's cars were much more utilitaran in design as they were intended for transporting animals of lesser value and inclusion in standard freight train consists. The Keystone fleet eventually grew to more than 1,000 cars.

Many of the cars finished out their days in maintenance of way (MOW) service.

Circus use

Many circuses, especially those in the United States in the latter 19th and early 20th centuries, featured animals in their performances. Since the primary method of transportation for circuses was by rail, stock cars were employed to carry the animals to the show locations.

The Ringling Brothers and Barnum and Bailey Circus, which still travels America by rail, uses special stock cars to haul their animals. When a Ringling Brothers train is made up, these cars are placed directly behind the train's locomotives to give the animals a smoother ride. The cars that Ringling Brothers uses to haul elephants are custom-built with extra amenities for the animals, including fresh water and food supply storage, heaters, roof-mounted fans and water misting systems for climate control, treated, non-slip flooring for safety and easy cleaning, floor drains that operate whether the train is moving or not, backup generators for when the cars are uncoupled from the locomotives, and specially-designed ramps for easy and safe loading and unloading. Some of the cars even have built-in accommodations for animal handlers so they can ride and tend to the animals at all hours.

Fish cars

In the 1870s the railroads of America were called upon to transport a new commodity: live fish. The fish were transported from hatcheries in the Midwest to locations along the Pacific coast to stock the rivers and lakes for sportfishing. The first such trip was made in 1874 when Dr. Livingston Stone of the U.S. Fisheries Commission (which later became the United States Fish and Wildlife Service) "chaperoned" a shipment of 35,000 shad fry to stock the Sacramento River in California. The fish were carried in open milk cans stowed within a conventional passenger car. Dr. Stone was required to change the water in the cans every two hours when fresh water was available. The majority of the fish made the trip successfully and the result was a new species of shad for western fishermen.

In 1881, the Commission contracted and built specialized "fish cars" to transport live fish coast-to-coast for stocking. The technologies involved in hauling live fish improved through the 1880s as new fish cars were built with icing capabilities to keep the water cool, and aerators to reduce the need to change the water so frequently. Some of the aerators were designed to take air from the train's steam or air lines, but these systems were soon deprecated as they held the potential of reducing the train's safe transit; the air lines on a train were used in later years to power the air brakes on individual railroad cars.

Fish cars were built to passenger train standards so they could travel at higher speeds than the typical freight trains of the day. Also, by putting fish cars into passenger trains, the cars were held at terminals far less than if they were hauled in freight trains. Fish car service, throughout their use, required that the fish keepers ride along with the cargo; a typical fish car crew consisted of five men, including a "captain" who would coordinate the transportation and delivery, several "messengers" who would serve as freight handlers and deliverymen, and a cook to feed the crew. The cargo's need for speedy transportation and passenger amenities for the crew necessitated the cars' inclusion in passenger trains.

Fish car operations typically lasted only from April through November of each year, with the cars held for service over the winter months. The cars became a bit of a novelty among the public and they were exhibited at the 1885 New Orleans Exhibition, the 1893 Chicago World's Fair, and the 1901 Pan-American Exposition in Buffalo, New York. As fish cars became more widely used by hatcheries, they were also used to transport regional species to non-native locations. For example, a fish car would be used to transport lobster from Massachusetts to San Francisco, California, or to transport dungeness crab back from San Francisco to the Chesapeake Bay.

The first all-steel fish car was built in 1916. Fish car technology improved again in the early 1920s as the milk cans that had been used were replaced by newer tanks, known as "Fearnow" pails. The new tanks were about 5 pounds (2.3 kg) lighter than the milk cans and included integrated containers for ice and aeration fittings. One 81- foot (26.7 metre) long car, built in 1929, included its own electrical generator and had enough capacity to carry 500,000 young fish up to 1 inch (2.5 cm) long. Fish car use declined in the 1930s as fish transportation shifted to a speedier means of transport by air, and to trucks as vehicle technology advanced and road conditions improved. The US government operated only three fish cars in 1940, with the last of this fleet taken out of service in 1947.

In 1960, Wisconsin Fish Commission "Badger Car #2" was sold to the Mid-Continent Railway Historical Society, where it was restored and is today a part of the Society's collection of historic rolling stock.

Poultry cars

From about 1890 to 1960, shipping live chickens and other birds by rail in special "henhouses on wheels" was commonplace. The cars featured wire mesh sides (which were covered with cloth in the winter to protect the occupants) and a multi-level series of individual coops, each one fitted with feed and water troughs. A human attendant traveled on board in a central compartment to feed and water the animals along the way. The cars were also equipped with a coal stove that provided heat for the centre of the car.

The concept is thought to been the brainchild of William P. Jenkins, a freight agent for the Erie Railroad. Jenkins collaborated with a Muncie, Indiana poultry dealer by the name of James L. Streeter on the design of a specialized car designed solely for transporting live fowl. The Live Poultry Transportation Company was formed about the same time that the first poultry car patent was issued ( August 24, 1884). By 1897, the company had 200 units in operation.

The Continental Live Poultry Car Company, a rival concern, was founded in 1890. Continental thought to dominate the market by offering larger cars, capable of transporting as many as 7,000 chickens in 120 coops, but the oversized cars failed to gain wide acceptance, and the firm closed its doors after just a few years in business.

Modern conversions

In the 1960s, the Ortner Freight Car Company of Cincinnati, Ohio developed a triple-deck hog carrier for the Northern Pacific Railway based on the design of 86-foot long "hi-cube" boxcar called the "Big Pig Palace." They later brought out a double-deck version called the "Steer Palace" that hauled livestock between Chicago and later Kansas City to slaughterhouses in Philadelphia and northern New Jersey until the early to mid 1980s on Penn Central and Conrail intermodal trains.

The Union Pacific Railroad, in an effort to earn more business hauling hogs from Nebraska to Los Angeles for Farmer John Meats, converted a large number of 50-foot auto parts boxcars into stock cars. Originally built by Gunderson Rail Cars in Portland, Oregon for the Missouri Pacific Railroad, the conversions were done by removing the boxcars' side panels and replacing them with panels that included vents that could be opened or closed. The tri-level cars featured built-in watering troughs.

Strings of 5-10 of these "HOGX" cars were, until recently, hauled twice weekly at the front of double-stack intermodal freight trains. In spite of the technological improvements in these new car designs, they were unable to overcome the advantages of highway transport of livestock. The units have since been scrapped.