Brass instrument

2007 Schools Wikipedia Selection. Related subjects: Musical Instruments

A brass instrument is a musical instrument whose tone is produced by vibration of the lips as the player blows into a tubular resonator (mouthpiece). They are also called labrosones, literally meaning "lip-vibrated instruments" (Baines, 1993).

To effectively change pitch on a valved brass instrument, two things come into play: the pressing of valves to effectively change the length of the tubing, and the player's lip aperture or "embouchure" setting, which determines the frequency of the pulsed air or vibrations into the instrument.

The view of most scholars (see organology) is that the term "brass instrument" should be defined by the way the sound is made, as above, and not by whether the instrument is actually made of brass. Thus, as exceptional cases one finds brass instruments made of wood, like the alphorn, the cornett, and the serpent, while many of woodwind instruments are made of brass, like the saxophone.

Families of brass instruments

Modern brass instruments generally come in one of two families:

- Valved brass instruments use a set of valves (typically 3 or 4 but as many as 7 or more in some cases) operated by the player's fingers that introduce additional tubing into the instrument, changing its overall length. This family includes all of the modern brass instruments except the trombone: the trumpet, horn, euphonium, and tuba, as well as the cornet, flügelhorn, baritone horn, sousaphone, mellophone, and the old saxhorn. As valved instruments are predominant among the brasses today, a more thorough discussion of their workings can be found below. The valves are usually piston valves, but can be rotary valves. Rotary valves are the norm for the horn and are also prevalent on the tuba.

- Slide brass instruments use a slide to change the length of tubing. The main instruments in this category are the trombone family, though valve trombones are occasionally used, especially in jazz. The trombone family's ancestor the sackbut and the folk instrument bazooka are also in the slide family.

There are two other families that have now become functionally obsolete for practical purposes, though instruments of both types are sometimes used for period-instrument performances of Baroque- or Classical-era pieces.

- Natural brass instruments, where the player can only play notes in the instrument's harmonic series, for example the bugle. The trumpet was a natural brass instrument prior to about 1795, and the horn before about 1820. Natural instruments are still played for some ceremonial functions, as well as period performances.

- Keyed or Fingered brass instruments used holes along the body of the instrument, which were covered by fingers or by finger-operated pads (keys) in a similar way to a woodwind instrument. These included the cornett, serpent, ophicleide and keyed trumpet. They are more difficult to play than valved instruments.

Some other wind instruments

- Alphorn (wood)

- Conch ( shell)

- Didgeridoo (wood, Australia)

- Natural horn

- Shofar ( horn)

- Vladimirsky rozhok (wood, Russia)

- Wagner tuba

Valves

As noted above, valves allow brass players to change pitches. When pressed, each valve changes the pitch by diverting the air stream through additional tubing, thus lengthening the instrument and lowering the harmonic series on which the instrument is vibrating (it is possible, though rare, for this behaviour to be reversed, i.e., that pressing the valve removes a length of tubing rather than adding one). The additional tubing usually features a short tuning slide of its own for fine adjustment of the valve's tuning, except when it is too short to make this practicable.

The two major types of valves are rotary valves and piston valves. The first piston valve instruments were developed just after the start of the 19th century. The Stölzel valve (invented by Heinrich Stölzel in 1814) was an early variety. In the mid 19th century the Vienna valve was an improved design. However most professional musicians preferred rotary valves for quicker, more reliable action, until better designs of piston valves were mass manufactured towards the end of the 19th century. Since the early decades of the 19th century, piston valves have been the most common on brass instruments.

Valves are employed in combination to play different notes. One scheme for deciding what valve does what has become a universal standard. The following list shows how each valve or combination of valves will affect the pitch from a given partial; this is true of all modern brass instruments.

- second valve - one half step

- first valve - one whole step

- first and second valves - one and a half steps. This is also achievable by third valve alone but the note will usually be flat (see below).

- second and third valves - two whole steps

- first and third valves - a perfect fourth, or two and a half steps. This combination will be noticeably sharp unless some means of compensation is used.

- first, second, and third valves - a tritone, or three whole steps. Will be very sharp unless some means of compensation is used.

Note that the mentioned tuning deficiencies are unavoidable; they are inherent in the construction of the instrument (see below).

In most trumpets and cornets, the "compensation" must be provided by extending the third valve slide with the fourth finger, and the first valve slide with the left hand thumb, to lower the pitch of 1-3 and 1-2-3 combinations. These notes on the trumpet and cornet for example, are ones that use these fingerings, such as low D, low C♯, and low F♯. So chromatically, to stay in tune, one must use this method.

In instruments with a fourth valve, such as tubas, euphoniums, and piccolo trumpets, that valve lowers the pitch by a perfect fourth; this is used partly to compensate for the sharpness of the final two valve combinations (4 for 1-3, 2-4 for 1-2-3). Of course, the other three valves can be used as normal to lower the pitch in combination with the fourth valve, so a fourth valve also extends the instrument's range downward by a perfect fourth, though with increasingly severe intonation problems.

When four-valved models without any kind of compensation play in the corresponding register, the sharpness becomes so severe that players must finger the note a half-step below the one they are trying to play. This eliminates the note a half-step above their open fundamental.

To correct for these problems, manufacturers of low brass instruments may choose one or a combination of four basic approaches, whose respective merits are subject to debate:

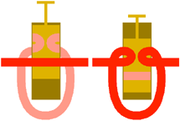

Compensation system

In the Compensation system, each of the first two (or three) valves has an additional set of tubing extending from the back of the valve. When the third (or fourth) valve is depressed in combination with another one, the air is routed through both the usual set of tubing plus the extra one, so that the pitch is lowered by an appropriate amount. This allows compensating instruments to play with accurate intonation in the octave below their open second partial, which is critical for tubas and euphoniums in much of their repertoire.

The compensating system was applied to French horns to serve a different purpose. It was used to allow a double horn in F and B flat to ease playing difficulties in the high register. In contrast to the system in use in tubas and euphoniums, the default 'side' of the horn is the longer F horn, with secondary lengths of tubing in coming into play when the first, second or third valves are pressed; pressing the thumb valve takes these secondary valve slides and the extra length of main tubing out of play to produce a shorter B-flat horn. A later "full double" design has completely separate valve section tubing for the two sides, and is considered superior, although rather heavier in weight.

Additional valves

Initially, compensated instruments tended to sound stuffy and blow less freely due to the air being doubled back through the main valves. In early designs, this led to sharp bends in the tubing and other obstructions of the air-flow. Some manufacturers therefore preferred adding more 'straight' valves instead, which for example could be pitched a little lower than the 2nd and 1st valves and were intended to be used instead of these in the respective valve combinations. While no longer featured in euphoniums for decades, professional tubas are still built like this, with five valves being the norm on CC- and BB♭-tubas and five or six valves on F-tubas.

Compensating double French horns can also suffer from the stuffiness resulting from the air being passed through the valve section twice, but as this really only affects the longer F side, a compensating double can be very useful for a 1st or 3rd horn player, who uses the F side less.

Additional sets of slides on each valve

Another approach was the addition of two sets of slides for different parts of the range. There used to be euphoniums and tubas built like this, but today, this approach has become highly exotic for all instruments - except French horns for which it is the norm, usually in a double, sometimes even triple configuration.

Trigger mechanism

A mechanical lever is provided to pull out the main tuning slide or a valve slide. This mechanism is used to aid intonation on notes that are naturally out of tune in a specific register of the instrument, it allows for speedy adjustment whilst playing and is sprung in such a way to that it returns to its original position after operation. Some examples of instruments that utilize the trigger are:

Cornet

Triggers are often found on the first and third valves. They are used to adjust the lower D, Ab, G and Gb in particular along with the higher D, F, and Bb. Due to the mechanics of the trigger it can often get stuck, and a "throw" (similar to trigger but without a spring) is preferred.

Trumpet

Similar to the cornet, however third valve slides are not as common- a throw is almost always used on the third slide as, due to its slightly augmented length, failure of the mechanism is common.

Euphoniums

A euphonium occasionally has a trigger on the tuning slide, to aid intonation on the F, F# and G.

Sound production in brass instruments

Because the player of a brass instrument has direct control of the prime vibrator (the lips), brass instruments exploit the player's ability to select the harmonic at which the instrument's column of air will vibrate. By making the instrument about twice as long as the equivalent woodwind instrument and starting with the second harmonic, players can get a good range of notes simply by varying the tension of their lips (see embouchure). Brass players call each harmonic a "partial" because it causes only a part of the tubing to vibrate (whereas at the fundamental the entire tubing will vibrate).

Most brass instruments are fitted with a removable mouthpiece. Different shapes, sizes and styles of mouthpiece may be used to suit different embouchures, or to more easily produce certain tonal characteristics. Trumpets are characteristically fitted with a cupped mouthpiece, while horns are fitted with a conical mouthpiece.

One interesting difference between a woodwind instrument and a brass instrument is that woodwind instruments are non-directional. This means that the sound produced propagates in all directions with approximately equal volume. Brass instruments, on the other hand, are highly directional, with most of the sound produced traveling straight outward from the bell. This difference makes it significantly more difficult to record a woodwind instrument accurately. It also plays a major role in some performance situations, such as in marching bands.

Materials

Brass instruments are normally made of brass, polished and then lacquered to prevent corrosion. Some quality instruments use gold plating to prevent corrosion.

They have also been constructed from other alloys containing significant amounts of copper or silver. These alloys are all biostatic because of the oligodynamic effect, and thus suppress growth of molds, fungi or bacteria. Horns constructed of stainless steel and aluminium do not sound bad, but are rapidly colonized by microorganisms and become unpleasant to play.

Most quality instruments are designed to prevent or reduce galvanic corrosion between any steel in the valves and springs, and the brass of the tubing. This design may take the form of desiccant design, to keep the valves dry, sacrificial zincs, replaceable valve cores and springs, plastic insulating washers, or nonconductive or noble materials for the valve cores and springs. Some instruments use several such features.

Didactics

Children may start to learn a brass instrument as soon as all their permanent teeth have arrived, usually at age 11. It is possible to start earlier, but while the teeth are still changing the embouchure will need occasional adjustment, and pressure on the lips and teeth may have undesirable effects.